Optimal planning of your shop starts with good heavy-duty shop management software. Good planning will not only make the mechanic’s job easier, but it will also allow your assets to get back on the road, where they are most profitable. It will also allow you to know the possible available resources, whether human or material, to effectively use the forces of your mechanics and finally to know and manage your preventive maintenance and your warranties.

In this video, Justin Watson, one of our experts, explains the importance of properly plan and structure your heavy-duty shop.

Know the Available Resources

When you schedule a repair or preventative maintenance, a good CMMS software will let you see your parts inventory in real time to ensure that you have what you need on hand before starting the job. You will be able to link different parts to certain tasks or maintenance, making it easier for the mechanic to know which parts to use on which unit.

In addition to having your parts inventory in real time, a good software will allow you to know which units are available in your yard in real time. When connected to your telematics solution, a good software will offer geofencing position tracking. This will give you the GPS coordinates of your units, facilitating decision-making regarding task planning.

Know the Available Workforce

A good heavy-duty shop software for trucks and heavy equipment will allow you to view the schedule of each of your mechanics in a calendar. You should be able to easily assign different tasks to the available mechanics, but also plan it according to their strengths and weaknesses. For example, if Jason is a specialist in everything related to the engine, you can assign him all the engine-related tasks and keep the simpler tasks (oil change, greasing, etc.) for a less experienced mechanic.

A big plus: Your heavy-duty shop management software should allow the manager to see what his team is working on in real time and how much time they spend on it. This means they will not only know the standard times, but also the exact time mechanics spend on different tasks, thus allowing access to reports on the performance and productivity of the employees. All this in order to optimize your planning by utilizing your mechanics’ strengths and seeing if the resources are sufficient.

Make Your Mechanics Independent

When your mechanics start their shift, all they need to do is log into their work station. From there, they will know exactly which units they need to work on and what task they need to do. With this process, your mechanics will become autonomous and proactive very quickly. You can even keep an eye on the garage without being physically present. By assigning tasks to your mechanics in advance, you reduce the risk of errors related to data entry, because you will be the one in charge of entering the correct codes into the system. The work order will be created automatically as soon as they start working, reducing the time your mechanics spend entering data.

With a good software, you will also be able to schedule tasks with a priority level without necessarily assigning them to a particular mechanic. This will allow them to have access to a list of miscellaneous tasks to get done for when they are finished with their own to-do list.

A Better Preventive Maintenance Management for Your Heavy Vehicles and Equipment

Your preventive maintenance must always respect minimum frequencies pre-established by the Ministry of Transport. When using maintenance software for heavy vehicles, you will be able to identify the different preventive maintenance due on your fleet using several frequencies: days, distance traveled, engine hours, fuel consumption and even by calendar on specific dates. When maintenance is due, the latter will notify you and you will be able to schedule the task to a mechanic or schedule an external PO.

Better Warranty Management

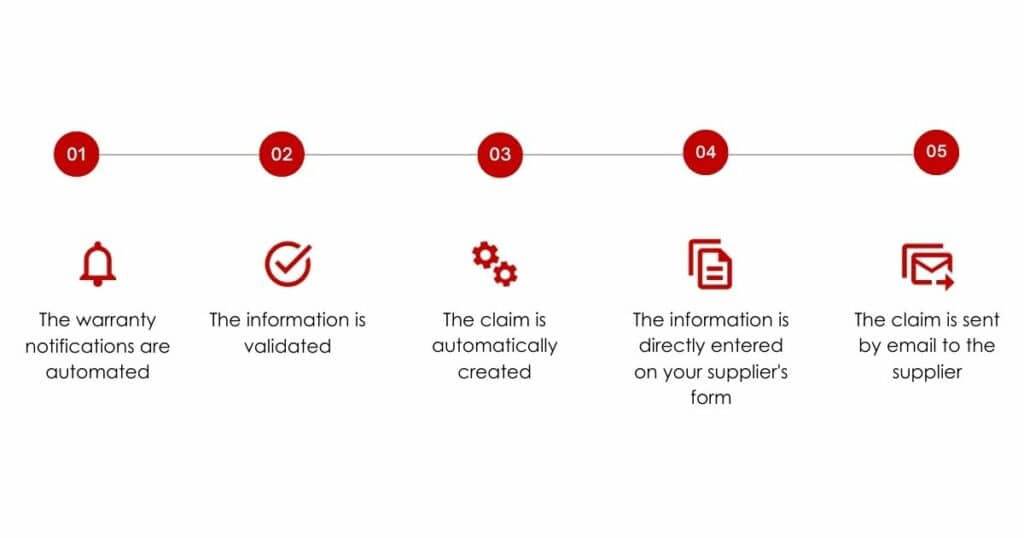

Just like the process for preventive maintenance, a good software will notify you when a warranty is expiring, which will allow you to plan repairs or maintenance accordingly. All information related to your unit will be gathered in the same place, allowing you to optimize your maintenance.

The image below shows the warranty management process:

Conclusion

A properly organized planning of your heavy-duty shop starts with acquiring a fleet maintenance management software adapted for heavy vehicles and equipment that will fit all your needs. By being able to visualize the global tasks for your garage and assign them to your mechanics according to their strengths, you will optimize your planning, making sure that your assets are back on the road as soon as possible.

Ready to take it to the next level? Request a demo now: