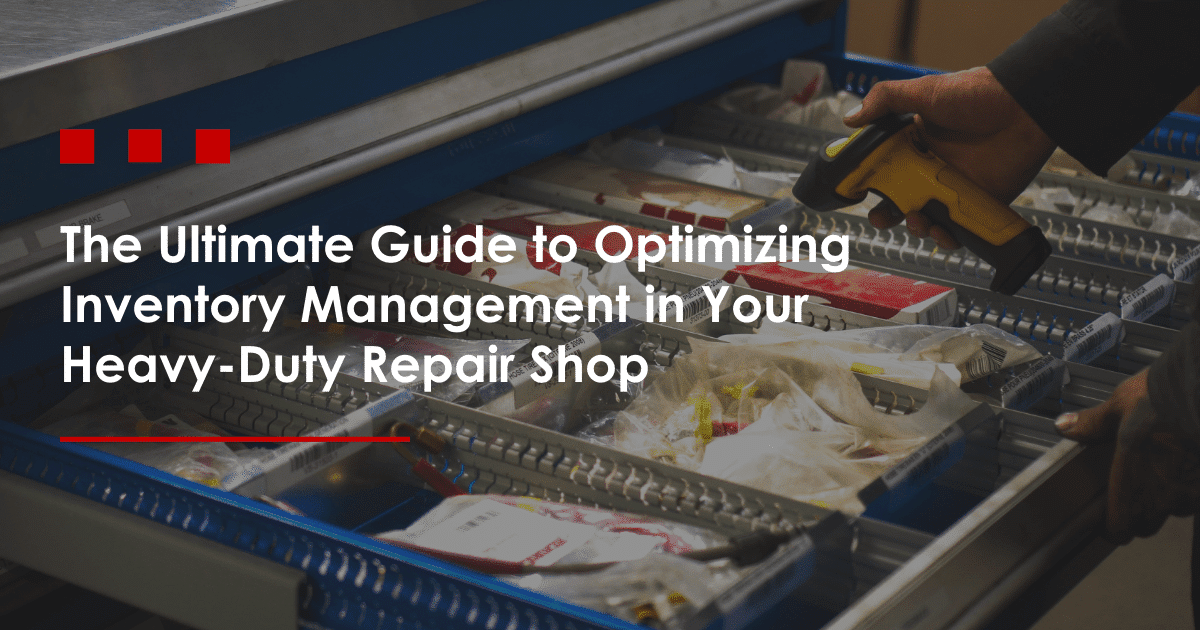

Effective inventory management is essential for the smooth operation of a heavy-duty repair shop. Without an organized system, shops can face stockouts, overstocking costs, and ultimately significant financial losses. Implementing a heavy-duty repair shop management software that includes inventory managementhelps solve these issues while improving productivity and profitability.

In this article, we’ll explore the must-have features of such software and the best practices to optimize your parts inventory management.

Why Is Optimized Inventory Management Crucial for Heavy-Duty Repair Shops?

You already know it: in the heavy-duty repair industry, time is money. A simple delay in part availability can lead to prolonged downtime, unhappy customers, and lost revenue. On the other hand, overstocking ties up capital and storage space unnecessarily.

A well-designed inventory management software ensures that the right parts are available at the right time, maintaining a balance between cost and availability.

The Key Benefits Include:

✅ Reduced downtime thanks to better parts availability.

✅ Lower costs by avoiding overstocking and unused parts losses.

✅ Improved inventory accuracy through automation and reduced human error.

✅ Increased customer satisfaction due to faster repair processes.

Must-Have Features of Inventory Management Software

If you’re looking for inventory management software for your shop, here are the essential features to prioritize:

1. Real-Time Parts Tracking

Having a real-time view of your inventory allows you to precisely track stock levels and anticipate part needs. With this strict monitoring, you can detect usage trends and make data-driven purchasing decisions.

📌 Did you know? If a specific part is frequently used in repairs, the system can send an automatic alert before it runs out of stock.

2. Automated Reordering System

Manual stock control is often error-prone and time-consuming. An automated reordering system uses minimum and maximum stock thresholds to trigger purchase orders automatically. By using this system as a safety net, you significantly reduce the risk of running out of parts, while still having the flexibility to place manual orders at any time.

📌 Did you know? MIR-RT software automatically generates internal and external orders when specific parts reach their critical threshold.

🔗Discover the inventory management features of MIR-RT

3. Barcode and RFID Label Integration

Using barcodes or RFID technology allows you to scan parts upon reception and automatically update inventory. This reduces human error and speeds up inventory checks. Additionally, mechanics’ jobs are greatly simplified when retrieving parts from the warehouse, as they only need to scan the required parts instead of manually entering them into work orders.

📌 Did you know? MIR-RT includes barcode scanning functionality that simplifies inventory adjustments and allows for more accurate tracking.

4. Integration with Shop Management Software

A standalone inventory system creates inefficient data silos and leads to duplicate data entry. It is crucial that your inventory management solution integrates with your maintenance management software to synchronize operations (ordering, invoicing, scheduling).

📌 Did you know? MIR-RT software includes 20 interconnected modules that allow seamless management of your heavy-duty repair shop.

5. Multi-Branch and Inter-Division Management

If you manage multiple repair shops or divisions, a system with centralized inventory visibility is a must. This feature simplifies part transfers between locations, optimizes stock levels, and reduces redundant and unnecessary orders.

📌 Did you know? In MIR-RT, you can easily switch between different branches and modify settings as needed, allowing for either independent or shared inventory management across various locations.

Best Practices to Optimize Your Inventory Management

Even with the best inventory management software, implementing best practices is essential to maximize efficiency.

1. Conduct Regular Inventory Checks

🔎 Why? Even with an automated system using min/max levels, physical inventory checks help prevent stock discrepancies and ensure data accuracy. A quarterly or semi-annual audit is recommended. This helps correct errors before they significantly impact your shop’s operations and profitability.

2. Use Demand Forecasting

📊 Why? By analyzing historical data, you can anticipate part needs and adjust purchase orders based on high-demand periods. Studying past trends to predict future needs is a highly effective strategy.

📌 Example: If you notice an increase in specific repairs during winter, stocking up on necessary parts in advance helps prevent stockouts and take advantage of better pricing.

3. Categorize Inventory for Maximum Efficiency

Implementing an ABC classification system helps prioritize inventory management:

- A Parts: High-value, low turnover → Strict control

- B Parts: Medium value, moderate turnover → Balanced management

- C Parts: Low value, high turnover → Bulk ordering

📌 Example: For effective management, strict monitoring of A parts is necessary, while automating C part orders can save time. Bolts would be classified as C parts, while engines would fall under A parts.

4. Train and Educate Your Team on Inventory Management

👨🏭 Why? A powerful software solution alone is not enough—your team must be well-trained to use it effectively and understand the importance of an organized inventory. Mechanics grabbing parts from the warehouse without scanning them can completely skew inventory data, requiring more frequent inventory checks than necessary.

📌 Example: Holding periodic training sessions ensures all personnel use the system correctly.

5. Utilize Reports and Dashboards

📊 Why? Modern inventory management software provides detailed reports on stock levels, part rotation, and purchasing trends. Taking a few minutes to analyze these reports can help you avoid major costs.

📌 Example: A real-time dashboard allows you to quickly identify critical parts and anticipate necessary purchase orders.

Conclusion

🚛 Managing inventory in a heavy-duty repair shop can be challenging, but with the right software and best practices, you can improve efficiency, profitability, and customer satisfaction.

📌 Next Step? Explore solutions like MIR-RT by DataDis to optimize your shop’s inventory management today.

🔗 Discover how DataDis can help you

Start optimizing your inventory management today and reduce your customers’ downtime!